A Case of IHKTECH's Cooperation with Europe CNC and Forging Parts Customers

Introduction

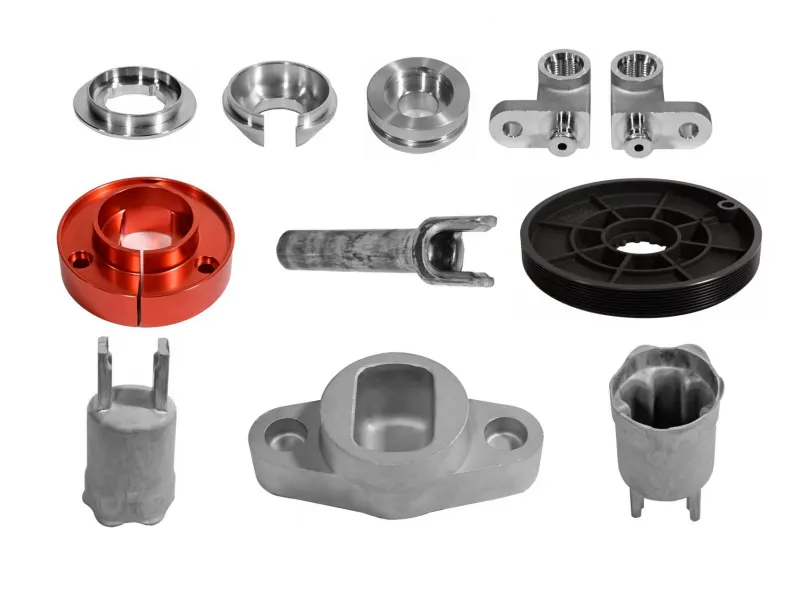

Our factory has been dedicated to the field of mechanical processing for decades, specializing in both CNC machining and forging. Equipped with advanced production equipment and a professional technical team, we have been committed to providing high-quality products to meet the diverse needs of global customers. This article will focus on a successful order case with an overseas client, which not only showcases our factory’s capabilities but also highlights the trust and cooperation established with international partners. This cooperation has significantly contributed to our factory’s growth and expansion in the global market.

I. The Initial Inquiry

A. The Customer’s Background

The customer, a well-established company based in Germany, operates in the automotive manufacturing sector. With over 50 years of history, they have been constantly expanding their market share in Europe and have recently set their sights on global expansion. Their product range covers various components for luxury vehicles, including engine parts, transmission components, and chassis systems. In order to meet the increasing demand for high-performance vehicles and comply with strict industry standards, they were in urgent need of reliable suppliers for high-quality CNC machined parts and forged components.

B. Their Specific Requirements

For the CNC machined parts, they required precision-engineered components with tolerances as tight as ±0.005mm. The materials specified included aluminum alloy 7075 and stainless steel 316L, which are known for their excellent strength-to-weight ratios and corrosion resistance. The parts ranged from complex gear housings to intricate valve bodies, with a total order quantity of 5,000 pieces for each type. In terms of forging, they needed connecting rods and crankshafts made of high-strength alloy steel 42CrMo. The forging ratio had to be strictly controlled between 3:1 and 5:1 to ensure optimal mechanical properties. The required surface finish for both machined and forged parts was Ra 0.8-Ra 1.6μm. The delivery time was set at 12 weeks from the date of order confirmation, which was a challenging but achievable target considering the complexity of the production process.

II. Our Factory's Response

A. Comprehensive Capability Introduction

Upon receiving the customer’s inquiry, our sales team immediately coordinated with the technical and production departments to conduct a detailed assessment. Our factory is equipped with over 100 sets of advanced CNC machining centers, including multi-axis machining centers with high precision and high speed, which can meet the complex processing requirements of various parts. In the forging workshop, we have large-tonnage forging presses and hammers, capable of handling forgings of different sizes and materials. The professional technical team consists of over 50 engineers and technicians, with an average of more than 10 years of experience in the industry. They are proficient in CAD/CAM software and various processing and forging techniques. Moreover, we have established a strict quality control system in line with international standards, from raw material inspection to finished product testing, ensuring that each product meets the highest quality requirements.

B. Customized Solution Proposal

Based on the customer’s specific needs, we proposed a customized solution. For the CNC machined parts, we recommended the use of high-precision cutting tools and advanced cooling systems to ensure dimensional accuracy and surface quality. By optimizing the machining process, we could reduce production time by 15% while maintaining quality. In terms of forging, we selected the appropriate forging ratio and temperature control parameters according to the characteristics of the alloy steel to improve the mechanical properties of the forgings. To control costs, we proposed to source raw materials from reliable domestic suppliers with competitive prices without compromising quality. For the production schedule, we developed a detailed plan with clear milestones and progress tracking mechanisms to ensure timely delivery. Weekly progress reports would be provided to the customer to keep them informed of the production status.

III. Negotiation and Communication

A. Overcoming Challenges

During the negotiation process, several challenges emerged. Firstly, in terms of technical standards, the customer had a strict quality control system based on German industry standards, which were more demanding than some international common standards. For example, the surface roughness requirement for certain critical parts was Ra 0.8μm, while our initial production process could only achieve Ra 1.2μm. To bridge this gap, our technical team conducted in-depth research and experiments. We optimized the cutting parameters, such as increasing the spindle speed and reducing the feed rate, and adopted advanced polishing techniques. After multiple trials, we successfully met the customer’s surface roughness requirements.

Price was another significant point of contention. The customer expected a lower price due to the large order quantity, while we had to consider production costs, including raw material prices, labor costs, and equipment depreciation. To find a balance, we provided a detailed cost breakdown to the customer, explaining the factors contributing to the price. At the same time, we proposed a phased price adjustment plan. If the order quantity increased by a certain percentage in subsequent orders, we would offer a corresponding discount. This approach not only demonstrated our sincerity but also provided an incentive for long-term cooperation.

Regarding the delivery time, the customer’s required 12-week delivery was tight considering the complexity of the parts and the production process. Our production department carefully analyzed the production capacity and formulated a detailed production schedule. By optimizing the production process, such as reducing setup times between different processes and increasing parallel processing of some components, we managed to meet the delivery deadline. Additionally, we established an emergency response mechanism. In case of any unexpected production disruptions, such as equipment failures or raw material shortages, we would immediately notify the customer and provide alternative solutions, such as expediting repairs or sourcing materials from backup suppliers.

B. Building Trust

Throughout the communication, our factory emphasized professionalism and integrity. Our sales team responded promptly to all of the customer’s inquiries, usually within 24 hours, providing detailed and accurate information. For instance, when the customer asked about the specific alloy composition and heat treatment process of our products, our technical experts prepared a comprehensive report, including technical data, test results, and industry comparisons. This level of responsiveness and detail impressed the customer and laid the foundation for trust.

To further enhance the customer’s confidence, we invited them to visit our factory. During the visit, we arranged a detailed tour of the production facilities, from the raw material warehouse to the final inspection area. The customer witnessed our strict quality control procedures, such as 100% inspection of critical dimensions and the use of advanced testing equipment like coordinate measuring machines and spectrometers. They also interacted with our production staff, who demonstrated their expertise and dedication. After the visit, the customer expressed their satisfaction and increased confidence in our ability to deliver high-quality products on time. This visit played a crucial role in finalizing the cooperation agreement.

IV. Production Process

A. Precision Machining

In the CNC machining stage, we utilized advanced 5-axis machining centers equipped with high-precision spindle systems, which could achieve rotational speeds of up to 20,000 RPM. This enabled us to perform complex milling, drilling, and turning operations with exceptional accuracy. For example, when machining the gear housings, the use of high-precision ball end mills with a diameter tolerance of ±0.002mm ensured that the tooth profiles and gear meshing surfaces met the strict design requirements.

To ensure quality control, we implemented a comprehensive inspection system. In-process inspections were carried out every two hours using precision measuring instruments such as micrometers and dial indicators. After the completion of each machining operation, a detailed dimensional inspection was performed with a coordinate measuring machine (CMM). Any deviations from the specified tolerances were immediately corrected by adjusting the machining parameters or replacing the cutting tools. This rigorous inspection process ensured that the final CNC machined parts had a defect rate of less than 0.1%.

B. Forging Excellence

The forging process began with careful material selection and heating. The alloy steel billets were heated in advanced electric resistance furnaces, which provided precise temperature control within a range of ±10°C. This ensured uniform heating and optimal plasticity for forging. The forging was carried out using a 5000-ton hydraulic press, which applied a controlled force to shape the billets into the desired connecting rods and crankshafts.

During the forging process, we employed closed-die forging techniques to ensure dimensional accuracy and improve the density and mechanical properties of the forgings. For instance, the forging ratio of the connecting rods was maintained at 4:1, which significantly enhanced their tensile strength and fatigue resistance. After forging, the parts underwent a series of heat treatment processes, including quenching and tempering, to further optimize their mechanical properties. The surface of the forgings was then machined to achieve the required surface finish, with roughness measurements taken at multiple points to ensure compliance with the Ra 0.8-Ra 1.6μm standard. This combination of precise forging and machining processes ensured that the forged components met the high-performance requirements of the automotive industry.

VI. After-sales Service and Long-term Cooperation

A. Customer Support

After the products were delivered, our after-sales service team remained highly active. We provided comprehensive technical consultation to the customer, covering installation guidance, operation training, and maintenance suggestions. For example, when the customer encountered difficulties in assembling the CNC machined parts, our technical experts immediately provided detailed assembly drawings and video tutorials, guiding them step by step to complete the installation.

In response to any quality issues or usage feedback, we established a rapid response mechanism. Once the customer reported a problem, our after-sales team would initiate an investigation within 24 hours. If it was determined to be a quality-related issue, we would take full responsibility. In one instance, a small number of CNC machined parts were found to have dimensional deviations during the customer’s assembly process. After receiving the feedback, we quickly analyzed the root cause. It turned out to be a minor adjustment error in the machining process. We immediately arranged for the production of replacement parts and expedited their delivery to the customer. At the same time, we provided a detailed report to the customer explaining the cause of the problem and the measures taken to prevent recurrence. This prompt and responsible approach not only resolved the customer’s problem but also further enhanced their trust in us.

B. Future Prospects

Looking ahead, we have established a clear plan for continued cooperation with this customer. In the short term, we are in discussions for an additional order of 3,000 sets of high-precision CNC machined parts and 1,000 forged components. These new orders will involve more complex designs and tighter tolerances, challenging our production capabilities but also presenting an opportunity for further growth.

To meet future demands, we are constantly upgrading our production facilities. We plan to introduce more advanced multi-axis CNC machining centers and high-tonnage forging presses in the next year to enhance our processing precision and production capacity. Additionally, we are investing in research and development to explore new materials and manufacturing processes. For example, we are researching the application of titanium alloys in automotive components to meet the industry’s growing demand for lightweight and high-strength materials.

In terms of service, we aim to further shorten the response time for customer inquiries and continuously improve the quality of after-sales service. We plan to establish a dedicated customer service center with multilingual staff to provide 24/7 support to our global customers. By maintaining a focus on quality, innovation, and customer satisfaction, we are confident in building a long-term and prosperous partnership with our international clients, further strengthening our position in the global market.

Conclusion

his successful case with the overseas customer not only demonstrates our factory’s strong technical capabilities and production capacity in CNC machining and forging but also showcases our ability to overcome challenges and build trust in international cooperation. Through effective communication, customized solutions, strict quality control, and timely delivery, we have achieved a win-win situation with the customer. Looking ahead, we will continue to focus on quality improvement, technological innovation, and customer service to meet the growing demands of global customers. We believe that by adhering to these principles, our factory will establish more long-term and stable partnerships with international clients, further enhancing our reputation and competitiveness in the global manufacturing market.

CONTACT INFORMATION

- Xinyi.ouyang@ihktech.com

- +86 15323384821

- 910-A03,9th Floor, Building 9 (Building 8 #), No.6, Nanjiang Second Road, Zhujiang Street, Nansha District, Guangzhou

You May Like

Have Anything To Ask Us?

Please fill in the detailed information in the form, and we will contact you as soon as possible!

Tagged case